Computer vision is a set of image processing techniques designed to understand the content of an image and enable automated system response. Combined with the rapid increase in available computing power, these algorithms are a powerful tool for automating industrial processes. So what can computer vision do for your company? Well, the possible applications of this technology are quite numerous in this publication we will try to describe a few of them.

Real-time computer vision allows you to continuously monitor production lines, control industrial robots, as well as support people in operations that require high precision. One example would be rotary and laser cutting, which, driven by algorithms guided by computer vision, gives much more space for detailed processing of parts. Algorithms can also automate certain functions related to simultaneous supervision of activities undertaken at various production nests and, depending on their status, send information to managers or take appropriate actions.

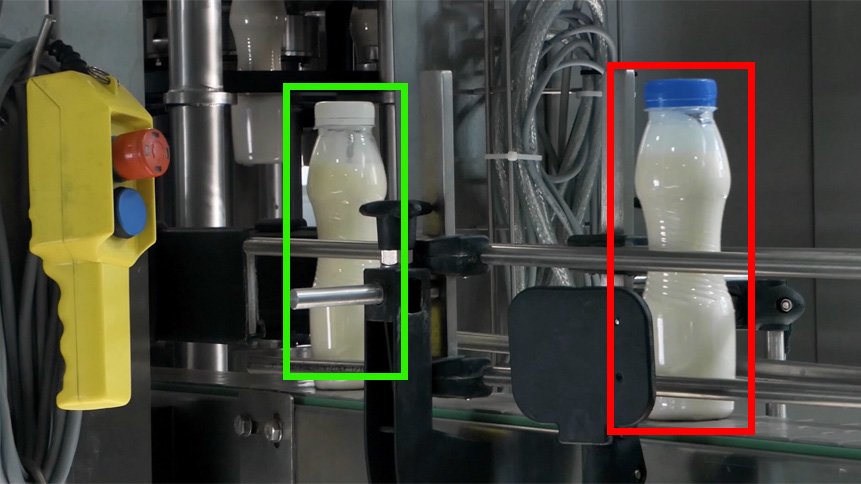

Most plants produce huge volumes of parts and finished products, which should be subject to quality assessment to detect defects created during the production process. One of the most common methods used is visual quality control, carried out by production workers to identify and eliminate defective parts. And in this case, such a task can be successfully entrusted to an automatic quality control system, monitoring the production line in real time with the help of a camera, the image from which is processed by appropriate trained models. Such a system is faster and more precise than human eyes and is ready to work 24 hours a day. If a defective product is detected, you can easily, using various integrations, alert personnel, control a production robot to remove such product from the line, or even stop the production line.

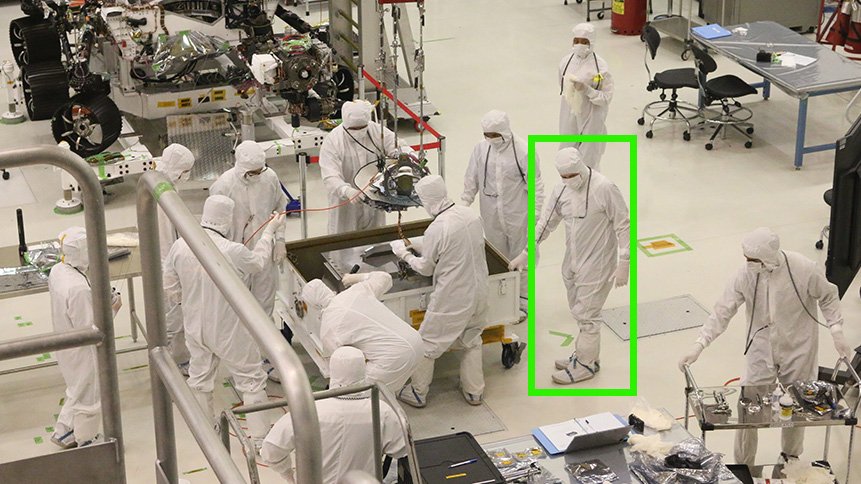

Workplace safety is one of the main areas of investment, and employee health is the most important goal of employers. Well-implemented procedures may save many of the related costs like personal costs, but also the costs that companies incur as a result of production line downtime. The question is how can we actively control whether employees follow the rules and use appropriate personal protective equipment in places where they should? Your surveillance system enhanced with the right computer vision algorithm can alert managers and employees in real time when safety policies are being violated to immediately prevent employee injuries in risk areas.

Inventory management isn’t just about skillful production planning, it’s also important to respond quickly to current needs based on current orders. AI algorithms can be trained to correctly identify individual items in your production line or warehouse. A system equipped with such technology can manage product inventory in an automated manner, already today some high-bay warehouses are using drones equipped with RFID systems, using computer vision algorithms, inventory taking becomes even simpler and more convenient.